Special Purpose Machine

Special Purpose Machine (SPM)

A special-purpose machine from SPM will improve your product quality, minimise part rejection and non-conforming parts, and increase your overall productivity.

Our experience and expertise are reflected in the cost-effective solutions we provide our customers.

special purpose machines supplied to our valued customers:

Automated Production Line:

An automated production line is comprised of a series of workstations linked by a transfer system and an electrical control system. Each station performs a specific operation, and the product is processed step by step as it moves along the line in a pre-defined production sequence.

Assembly & Testing:

Inventiatech’s wide range of experience in automated assembly applications allows us to carefully select suitable components and controls that best integrate into your custom assembly system.

We can integrate new steps into your existing production lines as well as provide turn-key solutions for various assembly tasks, including:

- Clip installation

- Screw and plan Nut driving

- Function and leak testing

- Impact testing

- Hose and tube assembly

- Tug testing

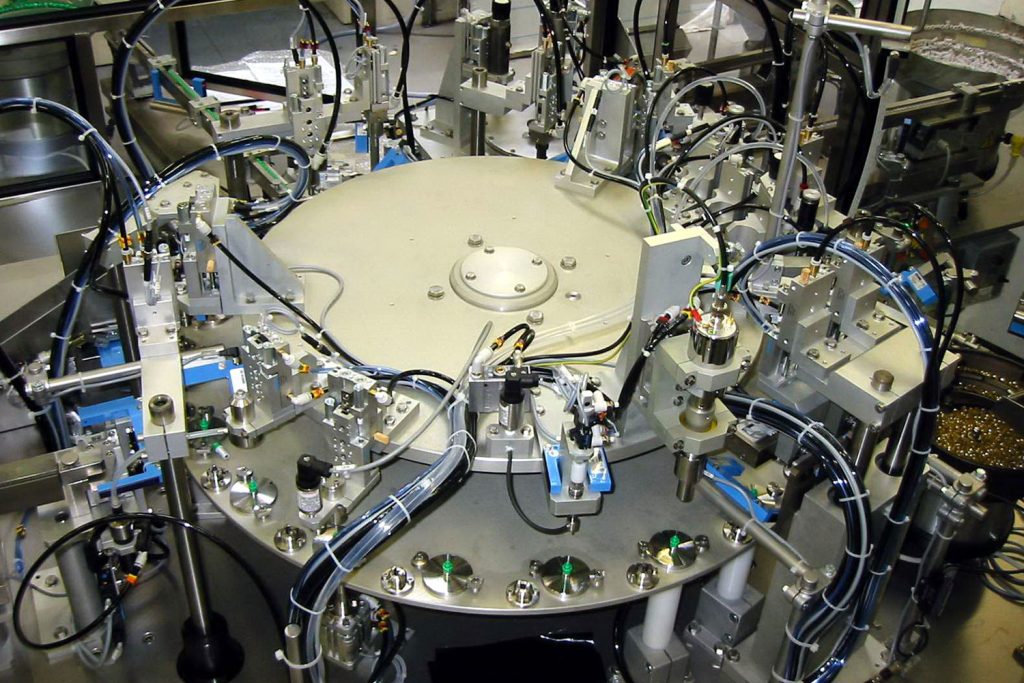

Rotary Indexing Table:

A rotary indexing table is specifically designed to make repetitive moves around a platform. Essentially, they are highly precise work-positioning devices that index parts to be worked or machined in multiple operations. The PRD ring drive system from Nexen is a high-resolution indexing system.

Used for:

A rotary table is a precision device that is ideal for work positioning. Such a table is used in metalworks as it makes the job of drilling easier for the metal worker. Other than this, the metal worker can also cut the piece on fixed axes during a specific interval with the help of a rotary table.

Advantage of rotary machine:

A great advantage of rotary is that the tooling is much more precise than flatbed tooling. So, you can cut multiple levels at the same time, not only middles or bottoms. If you have several layers of materials, those blades can be tooled to several different levels of that material all in the same tool.

Leak Testing:

What is leak test:

Leak testing is a procedure that inspectors use to determine whether an object or system is functioning within a specific leak limit. Leaks occur when there is a defect—a hole, a crack, or some other kind of flaw—in an object, allowing whatever liquid or gas it is holding to flow out.

The Advantages of Using Air Leak Testers

- Leak testing on production lines—such as those for automobiles and gas equipment—has been, up to now, one of the processes causing the most bottlenecks.

- A method often used in general is to seal air in a work, submerge it in water, then visually check for bubbles. The cons of this method include that it is impossible to ensure that none are overlooked, a drying process becomes necessary, and it cannot be automated.

- Many various testing units have been used in its place, but there were many unsatisfactory aspects, such as detection sensitivity, pressure resistance, running cost, and handling.