Jigs & Fixtures

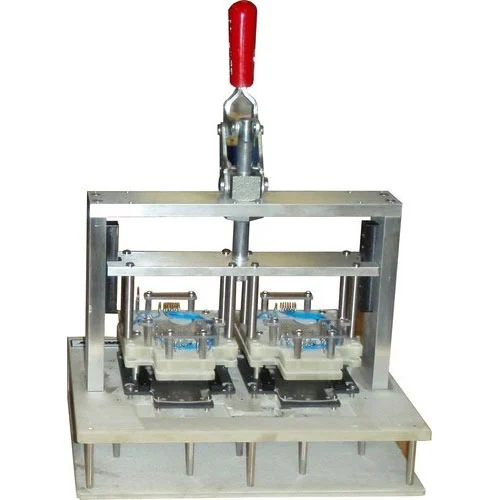

Test Jig

Inventiatech specialises in the design and manufacture of test jigs, fixtures test, and JIG measurement serving the size and product quality inspection in mechanical assembly lines, motor vehicles, and electronics with precision. high and optimal according to customer requirements. We have many years of experience in providing automated testing solutions, mechanical parts testing lines, and machine parts with jig systems that are high precision, flexible, and efficient.

A set of jigs, Jig Serve good test what benefits?

- Testing and testing jigs help determine the parameters of a product to compare with the output standard and customer requirements. A test fixture designed and engineered with the optimal solution provides accurate and clear results from measurements. Help the inspection department quickly determine whether the product meets the requirements or not.

- The inspection process takes place with high accuracy and productivity, reducing product costs and improving the competitiveness of enterprises.

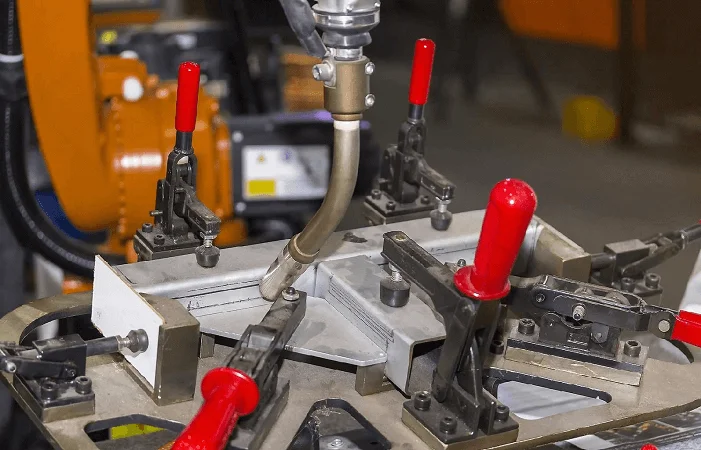

Mechanical JIG

Inventiatech is a leader in the design, manufacture, and assembly of jigs, serving clamps in machining, assembly, and inspection with high accuracy and optimal performance according to customer requirements. We have many years of experience in machine manufacturing, providing automation solutions in mechanical processing and manufacturing with accurate, flexible, and efficient fixtures.

Fixtures: JIGS is an indispensable product in the mechanical engineering industry. Referring to jigs, JIG refers to the task of clamping, positioning parts, and its products. The jigs are designed and manufactured primarily for three tasks with three corresponding classification names: machining jigs, assembly jigs, and test jigs.

Fixtures and Jig help ensure product quality during processing, assembly, and inspection. It is the first basis for other indicators to be born and to be valid if the jigs are correct. The first use of jigs and fixtures is for service-jigs for machining.

What are the benefits of a Jigs/Fixtures for good machining?

Functions and benefits of using this jig in accordance with its name. Specifically, the presence of jigs (JIG) before, during, and after the machining process (milling, turning, cutting, water jet cutting, etc.) to locate parts and workpieces and maintain that position during processing. From there, the machining programme can use the original coordinates as the standard. Determine the exact position of the workpiece compared to the cutting tool during machining. The use of good and optimised machining jigs not only helps to qualify machining, but it also helps the tasks to be done easily and quickly, reducing the time for setting.